Foundry Facilities

Moulding

We have Horizontal Flaskless DISA MATCH 24/28 Molding Machine. This molding line is having capacity of 120 molds per hour with cake size 700 × 600 × 250/250 and is based on latest pri-fill, shoot & squeeze technology, where the molding process will be extremely uniform which will finally result into highly consistent production by means of component weight, piece variation, mold variation, wall thickness, mold drawal with min. draft angle on pattern etc. This Machine was developed for higher quality molds & increased productivity.

Advantages of this Molding Systems are as under briefly.- Pre-fill, shoot and squeeze technology makes sure that mold quality are perfect, uniformaly & minimal variation even in deep cavity molds.

- No mold swelling which also directly affects the final weight of casting.

- Extra ordinary surface finish of casting.

- Min. machining allowance, reduces machining process time, cost and minimizes scrap generation.

- Min. man power required.

- Overall cost reduction in operation cost.

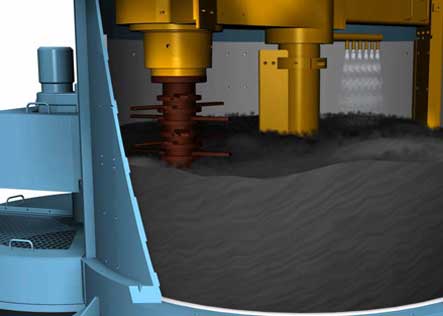

Sand Plant

DN Castech has installed a 40 ton per hour capacity sand plant from DISA. We have selected DISA for sand mixture and Green Sand Control system, with PLC interfaced load cell for return sand, new sand and additives like Bentonite, Coal Dust etc. with online moisture and sand testing facility. Also the homogeneity in mixing of Raw Material which also drastically reduces consumption of Bentonite, cold dust etc. Which also affect the quality of casting finish due to less generation of dead clay in sand.

Core Shop

- Cold Box Core Shooter.

- Shell Core Shooter.

Horizontal Parting, Cold Core Box Machine having 15 Litres capacity (Size: 450mm x 450mm x 200mm). Horizontal Parting, Cold Core Box Machine having 15 Litres capacity (Size: 450mm x 450mm x 200mm).

Melting

DN Castech has installed latest technology CI & Ductile Iron melting plant of 800 MT per month melt by 1200 KW panel, 500 Kgs × 2 Crucible dual-track medium frequency furnace from INDUCTOTERM with a melting capacity of 1.5 tons per hour.

This furnace is equiped with hydraulic tilting arrangements, water cool leads and standard set of bus bar & fume capture hoods for collecting smokes, dust & airborne pollutants during all phases of furnace operation.

In addition we have carbon and silicon analyzer with charge calculation.

Pattern Shop

We have in house Pattern Manufacturing Facilities.

Make Size X Y Z (mm)

TopWell TW1268 1200 x 800 x 550

Fettling & Shot Blasting

After shakeout casting will process in shot blasting machine and for grinding to remove scales and achieve clean & uniform surface textures.

- Hanger type shot blasting machine

- Heavy duty swing frame grinders

- Pedestal grinders

- Portable pneumatic grinders

- Wedge breaker for runner/riser cutting

Foundry Testing Facilities

Some of our Major Instruments in Foundry.

Spectrometer

Make : BrukerModel : Q4 Tasman

Analyzing no. of elements 17

Micro Structure Examination

Software & Make : Metal SoftAs per ASTM 8247

Chemical Analysis

We are checking major elements by wet analysis.

Hardness Testing

Brinell Hardness Tester3000 Kg. Load

Ball Size: 5mm (750 Kg.) & 10mm (3000 Kg.)

Universal Testing Machine

UTM Capacity of 200 KN

Sand Testing Analysis

Green Sand Control System(Automated Online Green Sand Controller from USA)

Sieve Shaker (AFS Analysis)

Permeability Tester

Universal Strength Testing Machine